CLEAN AIR SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CLEAN AIR SYSTEMS

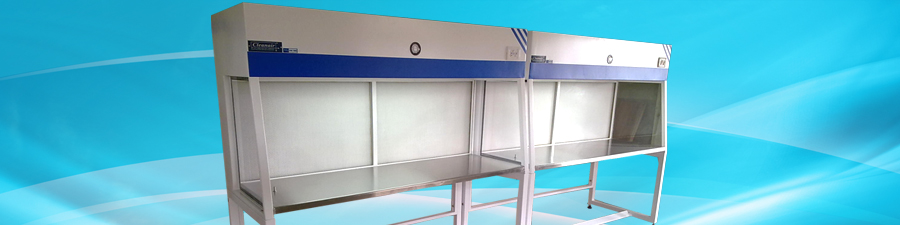

Laboratory Fume Exhaust Hood

Laboratory fume hoods are moderately covered workspaces that are exhausted to the outer side. The prime objective of laboratory fume hoods is to keep poisonous or irksome vapors out of the general laboratory working area. Another purpose is to serve as a protective layer between the worker and the equipment being used when there is the possibility of an explosive reaction, or to protect the specimen. Laboratory hoods are comprised of the hood itself and a sash, which is the front panel of the fume hood that can be opened and closed to maximize access and minimize airflow.

The efficiency of a laboratory hood is measured by its hood face velocity and required air flow. Hood face velocity is a measurement of air flow speed across the imaginary plane running between the bottom of the sash to the work surface. Generally measured in feet per minute (fpm), the greater the hood face velocity, the more quickly toxins and other vapors can be flushed from the system. Required airflow is related to hood face velocity in that it is a measurement of the amount of air flow required to achieve a laminar flow velocity of 100 feet per minute.

The Fume Cupboard is closed on three sides and front side provided with 5 mm thick polycarbonate sliding door. The fume chamber is provided with a centrifugal blower mounted on top of the Hood, coupled directly with a suitable motor for sucking the fumes from the hood and forcing it to go out to the atmosphere through the duct. The blower and casing will be made of mild steel with polyurethane paint coated / FRP finish.

Cleanair™ Laboratory Fume Exhaust hoods are readily available in metal construction with inner FRP lining or in complete FRP constructions. Heavy-duty and dynamically balanced blower assembly provided in the unit removes smoke / fumes / odor from any chemical process conducted in the hood. Work surface of these Fume Hoods is equipped with acid proof ceramic lining or with finely polished granite. The front sash is connected to suitably balanced counter weigh for convenient vertical sliding.

The Fume Hoods are also provided with suitable lighting inside the work chamber. They are available with or without storage cupboard under the workbench and are also available in ductless type also, with activated carbon filter to remove heavy odors. Standard features power points to work with any small electrical equipments, inlet nozzles for gas / air / vacuum etc. Optional features include water sink with inlet and outlet Flameproof electrical accessories such as FLP lighting, FLP motor & starter, FLP plug points Available in various sizes to suit user requirement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.